Base development.

A rotating base ensures the plant even exposure of light and demonstrates how the adjustable shade functions through the design of the lamp.

Stand technicality.

Exploring different variations of the stand of the lamp to determine the best position of the framework to create a stable base.

Shade & framework.

Ideation of the shade which, will compliment the style of the lamp and ensure the maximum amount of light is concentrated on the plant below.

Pivot point.

Small scale modelling using card and foam to determine how the base will rotate using a central pivot point and detent mechanisms.

Detent mechanism.

Testing using three detent bearings decide which amount would make the function of the base rotate most smoothly.

Exposed cable.

Using string to replicate how the cable would be exposed, wrap around and enter the lower base to connect to the battery.

Base development.

Card modelling to explore different possible shapes for the base and how this will connect several other components of the lamp.

Frame modelling.

Developing and testing how the cable will pass through the framework and the angle that will help do this with the least amount of friction on the product.

CAD designs.

Having the frame located in a position lined up to where the cable feeds out of the base reduces tension on the product.

Shade designs.

The weight of the shade will directly impact the function of the design. It needs to be heavy enough to pull on the cable and form resistance to the mechanism.

Cable route.

The cable will be exposed throughout the side of the framework to show it movement as the shades adjusted. The cable will then feed into the top section of the lamp.

3D print.

Component is key for ensuring the wire and shade hang central when adjusted via the base. A channel inside the component allows the cable to pass through.

Frame.

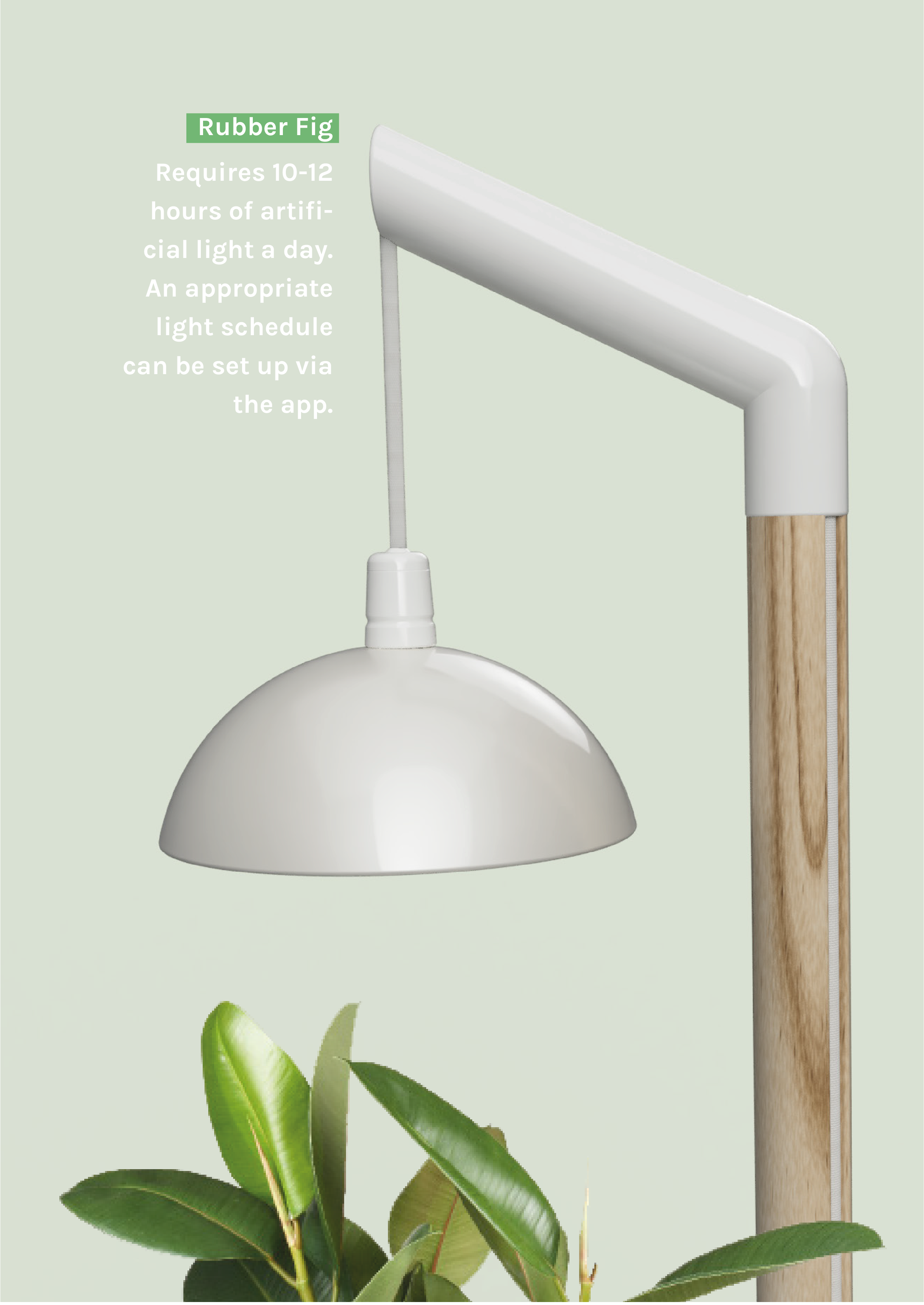

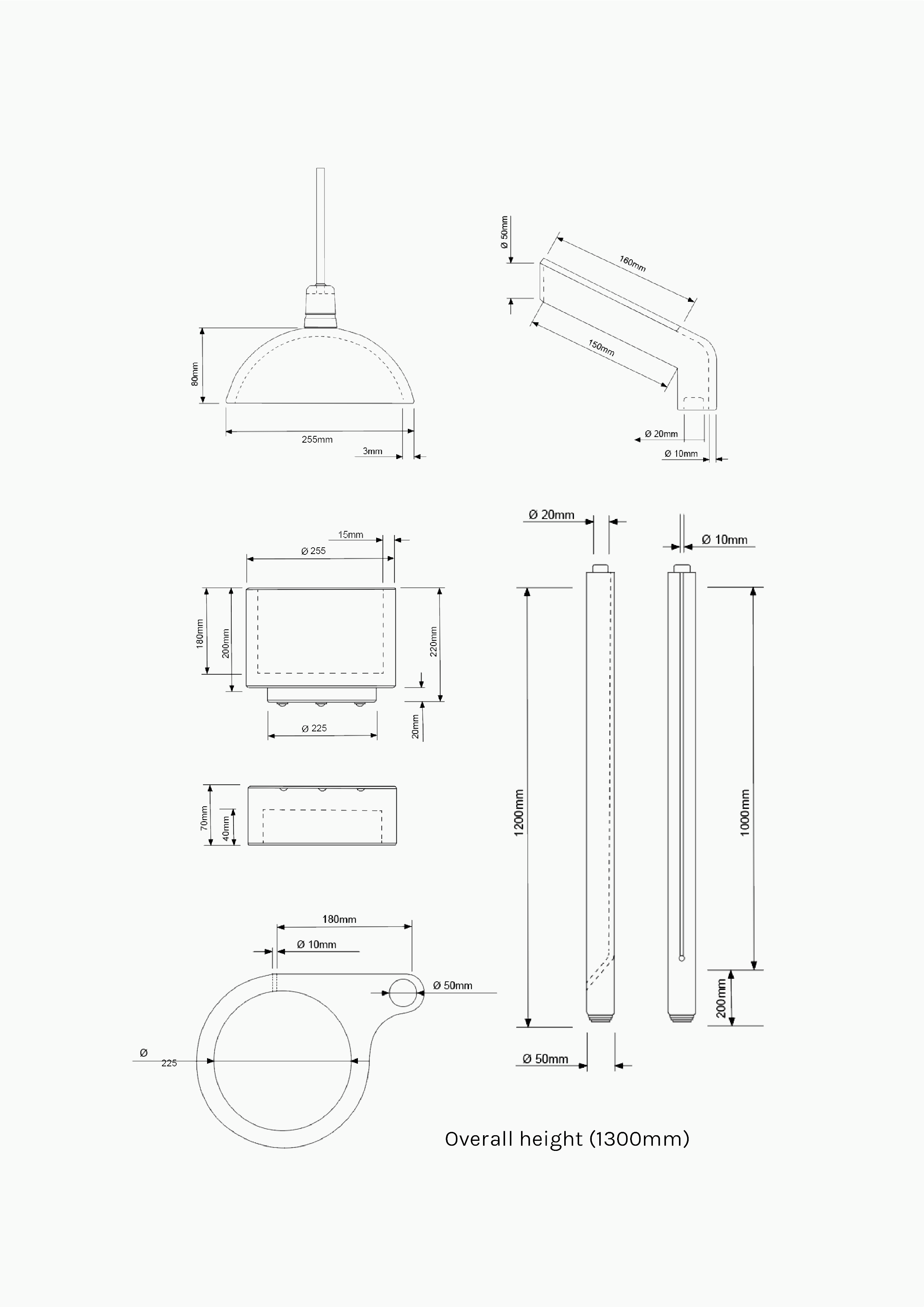

1) Main framework made from ash pole, with routed section and entrance / exit hole at either side.

2) 3D printed poly-lactic acid (PLA) component. Injection moulded for mass production.

3) 12 volt grow bulb will be used to light the product, as this won’t cause any safety concerns if in contact with water.

Base Mechanism.

1) Base made from Jesmonite moulding, treated with Jesmonite Acrylic Sealer to prolong surface durability.

2) Stand made from ash. The centre of the base secured with a screw, creating a sturdy pivot point.

3) Three detent ball and spring mechanisms will rotate around the base, allowing the top base rotation.

Shade.

1) The shade will be a white powder coated aluminium dome shape.

2) Shade switch will be outsourced and powder coated aluminium. Rotating feature also allows the light to be dimmed.

3) 10mm knitted electric cable will be exposed throughout the design to demonstrate its main function.

“This is a very clever design to solve a common problem in modern homes and flats!”

— Micaela, Plant Scientist

“Congratulations on a really great product! The colours and finishes you have chosen reflect the natural undercurrent to your product solution, with the white powder coated metal, stone effect and wood working well as neutral finishes that would not be obtrusive to most modern interiors.

— Abbie, Wilko designer